COB package, known as Chip on Board (ChipsonBoard, COB), is a technology to solve the problem of LED heat dissipation. Compared to DIP and SMD, it is characterized by space saving, simplified packaging operations, and efficient thermal management.

COB LED packaging uses the bare chip with conductive or non-conductive adhesive adhesive on the interconnect substrate, and then lead bonding to achieve its electrical connection. If the bare chip is directly exposed to the air, susceptible to contamination or man-made damage, affecting or destroying the function of the chip, so the chip and bonding leads with adhesive encapsulation.

Advantages of COB LED Packaging

| Advantage | Description |

| Super Lightweight | Due to COB uses thin PCBs (0.4-1.2mm), so their products three times lighter than traditional ones. You can save on costs for structure and transport. |

| Impact and Pressure Resistance | COB encases LEDs in PCBs with epoxy, making them smooth and tough. They resist bumps and scratches well. |

| Wide Viewing Angle | Through a wide angle over 175 degrees, They provide excellent light diffusion and color blending. |

| Flexibility | Unique to COB, the PCB can bend without damaging the LEDs. So, it is perfect for creating curved screens like those used in bars and nightclubs. |

| Strong Heat Dissipation | COB’s design speeds up heat removal through thick copper foils on PCBs. It can prevent severe light loss, leading to a longer lifespan. |

| Durable and Easy to Clean | The smooth, hard surface of the lights is easy to maintain. If dirty, just wipe with water or cloth. |

| All-Weather Features | Triple protection makes COB water, moisture, rot, dust, static, oxidation, and UV resistant. Works well in temperatures from -30°C to +80°C. |

What is SMD LED Packaging

Surface Mounted Devices, known as SMD. “In the early stages of electronic circuit board production, over-hole assembly was done entirely by hand. After the first automated machines were introduced, they could place some simple pin components, but complex components still needed to be placed manually for wave soldering.

Surface mount components were introduced about twenty years ago and ushered in a new era. Everything from passive components to active components and integrated circuits eventually became surface mount devices (SMDs) and could be assembled with pick-and-place equipment.

Features of SMD LED Packaging

| Feature | Explanation |

| High Assembly Density | SMDs make electronic devices smaller and lighter. They reduce size by 40% to 60% and weight by 60% to 80%. You get more power in less space! |

| High Reliability | They are very reliable with a strong ability to resist vibrations. The chance of soldering flaws is low. They keep things stable for you. |

| Good High-Frequency Traits | They have great high-frequency characteristics, reducing electromagnetic and radio frequency interference. |

| Automation and Efficiency | Due to SMDs are easy to automate, So, they improve production efficiency and cuts costs by 30% to 50%. They can save materials, energy, equipment, manpower, and time. |

Cob package and SMD packaging difference

| Aspect | SMD Technology | COB Technology |

|---|---|---|

| Process | Encapsulates light chips into beads, soldered onto PCB for unit module assembly, then assembled into LED screen. | -Directly solders light chips onto PCB, overall film coating for unit module assembly, then assembled into LED screen. |

| Product Differentiation | Point light source effect | Surface light source effect. COB offers better visual experience, higher contrast ratio (>20000:1), vivid colors. Higher contrast ratio, vivid colors, resembles LCD screen effect. Requires full screen calibration for consistency. May show inconsistent colors at wide viewing angles. |

| Reliability | Weaker protection, prone to damage, poor water/dust resistance, easy on-site maintenance. | Better protection (IP65 level), water/dust resistance, difficult on-site maintenance, requires professional repair equipment. |

| Energy Efficiency | Higher power consumption due to LED chip design. | Lower power consumption due to chip design, increased economy. Better transparency due to overall film coating, further improving energy efficiency. |

| Cost | Complex production, lower technical barriers, widespread competition. | High technical barriers, limited manufacturers, higher production costs. COB costs remain at a slight disadvantage compared to SMD screens. |

SMD Vs. COB LED display: Which Is Better?

For LED displays, SMD and COB LED display each have their own advantages and disadvantages:

SMD LED Displays:

Pros:

- Suitable for indoor and outdoor use, versatile in design, and offer a variety of module sizes.

- Wide range of brightness and pitch options to accommodate different price.

Cons:

- Can have a pixelated appearance at close viewing distances.

- Limited heat dissipation capabilities.

- Difficult to clean.

- Susceptible to damage during installation and shipping.

COB LED Displays:

Pros:

- It can Achieve smaller pixel pitch than SMD, so you can get clearer images.

- Surface light source allows for high refresh rates (>7680Hz) ;

- without eye strain during prolonged viewing.

- Excellent heat dissipation, with heat quickly dissipated through the PCB.

- Wide viewing angle (170°), operating temperature from -40°C to 80°C.

- Efficient heat dissipation results in long life (over 10 years)

- significant power savings (over 60% vs. SMD)

- common cathode and common anode drive modes options

Cons:

- Higher price point.

- Limited module size availability.

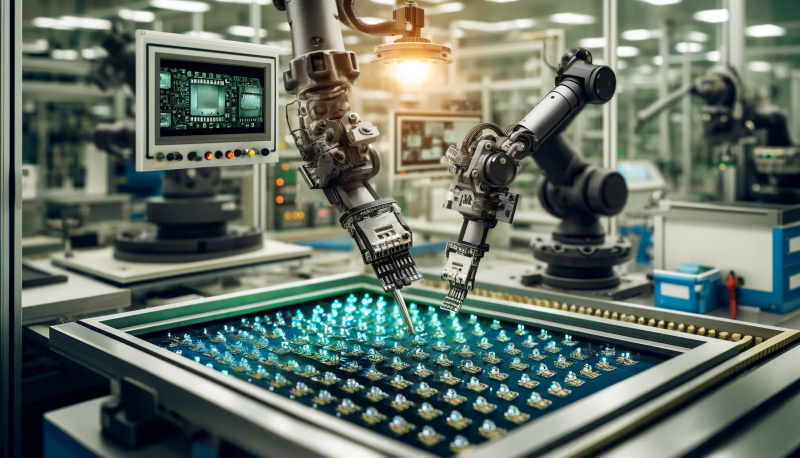

Currently, Due to cause equipment waste, COB LED displays have not been widely adopted, COB technology presents significant differences for companies. GDHANHENG has its own production processes, mass transfer technology and grayscale calibration technology. We can enure you get high product yield for COB displays.

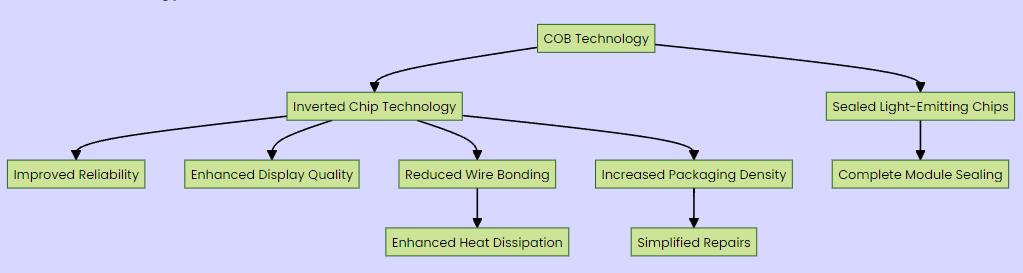

What’s so good about IAMLED WALL’s COB LED displays?

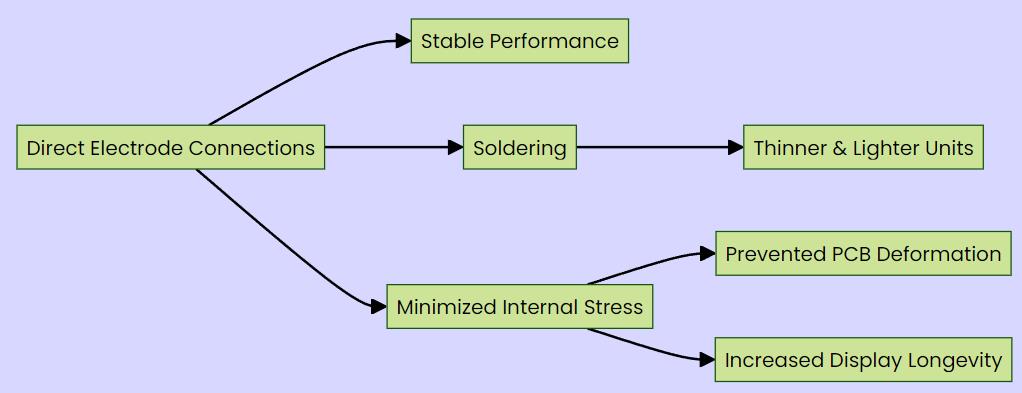

The chips of Our flip-chip COB LED display are sealed directly to the PCB. It can make the module completely sealed with a smooth, hard surface.

However, traditional COB LED displays use gold wires to connect the chips, which face up. It will produce reliability risks and affect the quality of the display. Our COB LED display eliminates the gold wires and uses only solder paste and phosphors. It improves heat dissipation and reduces common LED problems such as flickering and dimming.

Traditional methods are complex and can’t be repaired if a light fails. Our Flip-chip technology simplifies the process and makes repairs possible. It increases packing density by 16 times and reduces volume by 80%. So, you will get more uniform light distribution and lower costs.

Flip-chip COB can solve many problems, such as:

- It reduces the number of steps in the production line from 11 to 4

- LEDs can emit light at 180 degrees.

Overall, the packaging layer doesn’t require space for wires, making the devices extremely thin. It will reduce the impact of thermal expansion differences, prevent PCB deformation, and minimize LED damage, significantly extending the life of the display.When you purchase our COB LED screen, you will get many benefits as follows:

Ours COB LED Display benefits

Great quality:

- Our COB LED displays are very durable.

- They are shock-resistant, so you don’t have to worry about bumps during shipping.

- They can support five times more weight than SMD LED displays.

- Our IP65 COB LED display can resist various environmental damages such as water mist, oxidation, and electrical fire.

Amazing display:

- COB LED displays show beautiful images because they don’t have unnecessary steps like SMT or patch processes.

- There are no physical barriers between the pixels, you will get more finer, colors more saturated,

- Surface Light Source” technology minimizes moiré and reduces light refraction.

High Performance:

- Compared to SMD LED displays, Our COB LED displays are manufactured with fewer steps.

- Due to COB packaging technique seals the light-emitting chips directly to the circuit board, So, heat can be dissipated directly through the circuit board.

- In addition, Our COB LED displays consume 30% less power than SMD fine-pitch LED displays.

Conclusion:

In general, although COB LED display may be more expensive, a high-quality and stable COB LED display is a better option for a small-pitch LED screen when you have enough budget. As a top second-hand LED screen supplier, IAMLEDWAL can not only provide used COB LED screens at good price but also have a new screen option.If you have any needs in this regard, please feel free to contact us.