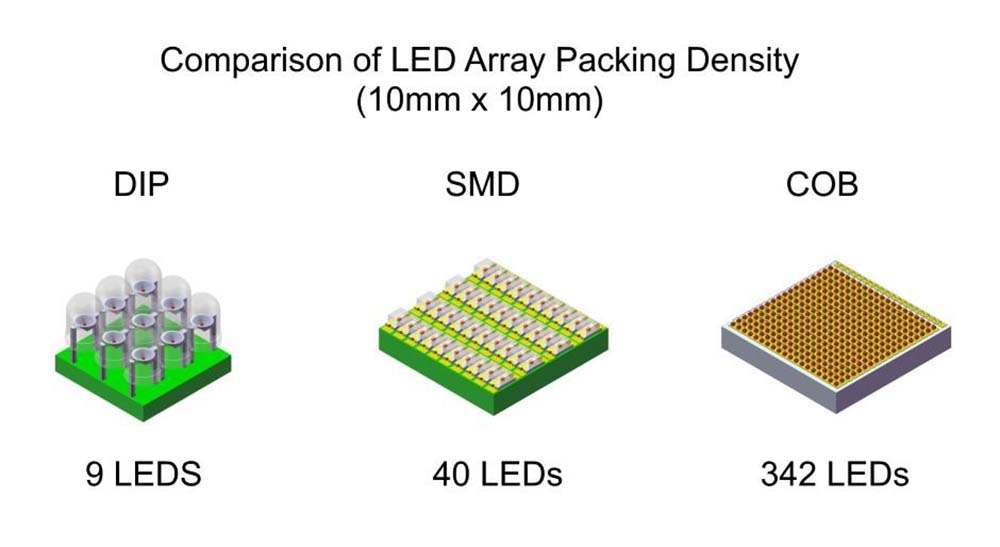

From traditional DIP outdoor LED screens to SMD indoor and outdoor LED screens, you may already be very familiar with SMD packaging technology. However, with the increase in people’s demand for higher-definition vision and the development of LED technology, COB LED screens have emerged. Do you know What is the difference between them? Is COB LED display better than SMD LED display? GDHANHENG will explore this topic in detail.

What is an SMD LED screen?

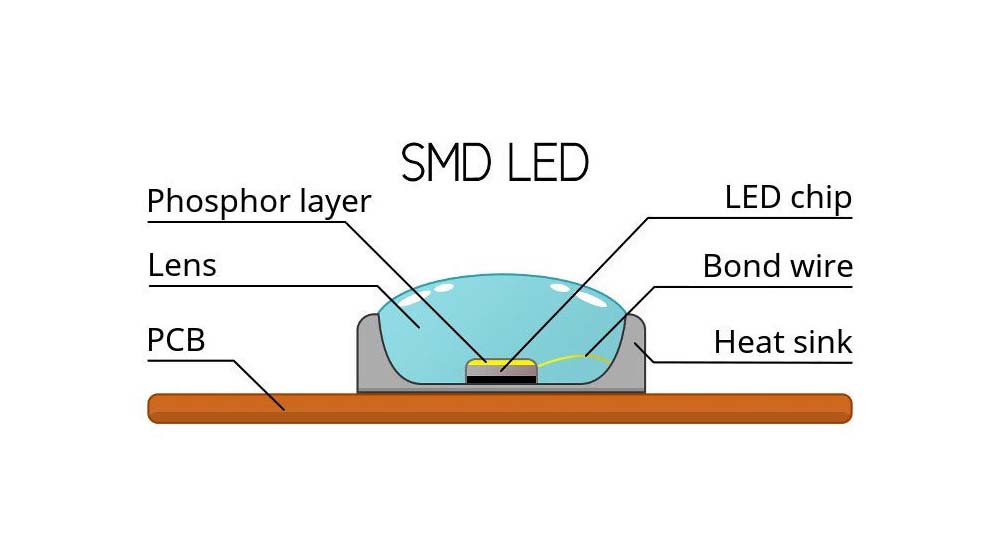

SMD LED screen refers to an LED display using Surface Mount Technology (SMT), which encapsulates lamps, brackets, chips, leads, epoxy resin and other materials into lamp beads of different specifications, and then welds them on the PCB board to form LED display module.

The LED lamp beads generally need to be exposed for SMD LED displays. It is not only prone to cross-light problems between pixels, but also makes the protective performance poor, affecting the imaging effect and service life.

The following are the characteristics of SMD LED screens:

- Small size: SMD LED chips are small in size and can achieve smaller pitch LED screens. For example, the pixel pitch can reach P1.5.

- High brightness: With the development of LED technology, If SMD LED chips use high-brightness luminescent materials, which can reach 7000-1000nit brightness and are suitable for outdoor high-brightness environments even if in direct sunlight.

- Energy-saving and efficient: Compared with traditional DIP LED screens, SMD LED screens consume less power and can provide energy utilization efficiency and save energy.

- Wide viewing angle: SMD LED screens have a wide viewing angle range. Generally, the maximum horizontal and vertical viewing angles can reach 160 degrees, allowing people to view the screen from a wider angle without color distortion.

- Rich colors: SMD LED screens can achieve 16-bit grayscale and display more colorful colors.

- High reliability: Compared with DIP LED display, SMD LED screen is more sturdy and reliable.

- Easy maintenance: Large SMD LED screens are usually assembled from different pixel pitch LED display modules. With the modular design, it can make maintenance more convenient. When a single module fails, it can be quickly replaced, reducing repair costs and time.

What is COB LED display?

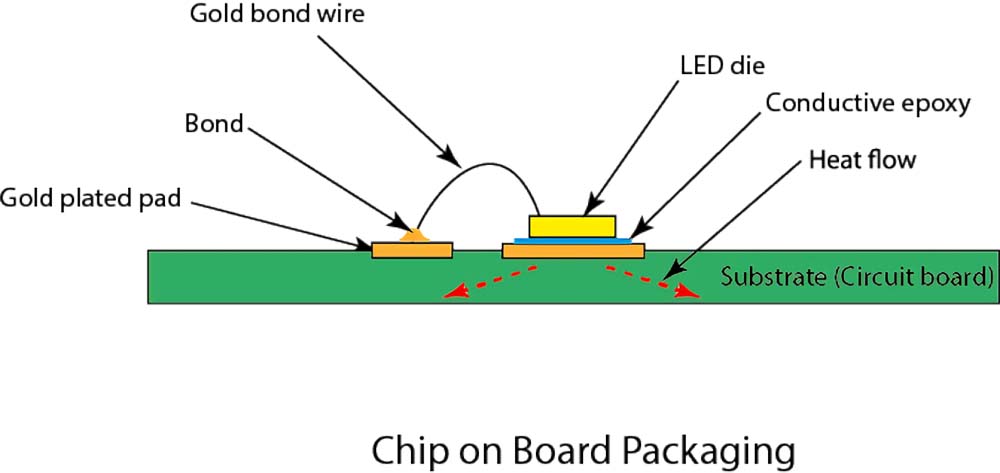

COB is the abbreviation of Chip On Board. The technology refers to the LED packaging technology that directly solidifies the LED chip on the printed circuit board (PCB board), rather than welding the formed LED packages on the PCB.

COB packaging technology has some advantages in terms of manufacturing efficiency, imaging quality, protection, and application of small and micro pitch.

The following are the characteristics of COB LED screens:

- Uniformity: Because LED chips are densely packed on the same substrate and share a layer of reflective material, COB LED screens are able to achieve more uniform light output.

- High resolution: Compared with SMD LED screens, COB LED screens can achieve smaller pixel pitch and achieve higher resolution, making the LED display content more delicate and clear.

- High reliability: The LED chip of the COB LED screen is sealed on the substrate and is less affected by the external environment, so it has high reliability and stability and a long service life.

- Easy maintenance: Since the COB LED screen adopts a modular design, faulty modules can be replaced relatively easily, reducing maintenance costs and repair time.

- Smaller size and weight: COB LED screens are lighter, easier to install and transport, and are suitable for various applications.

Comparison between SMD LED screen and COB LED screen

Contrast comparison

Using SMD packaging technology with Flip or Wire structure LED displays have a smaller chip emitting area, while flip-chip COB chips occupy a smaller proportion of the PCB and have no electrode obstruction, which improves the chip’s luminous efficiency. Under the same size, COB LED screen has higher brightness and higher contrast.

Large viewing angle comparison

Since the surface of the SMD LED screen has not been optically treated, it is easy to produce color casts and other phenomena when viewed from the side. However, the COB packaging technology is encapsulated with epoxy resin or silicone. The COB LED display has such advantages:

- The surface is flatter and smoother

- With wider horizontal and vertical viewing angles

- A wider color gamut.

- The light is soft and looks better.

Stability comparison

COB LED packaging can reduce thermal resistance and effectively solve heat dissipation problems. In addition, COB LED screens use larger-area electrodes to directly connect to the substrate, which improves the heat dissipation performance of electronic components, thereby effectively improving the color stability and service life of the LED display.

Reliability comparison

COB packaging technology does not require wire bonding, which can completely solve the failure problem of SMD caused by wire bonding, greatly reduce the risk caused by metal migration, and avoid the problem of SMD pad exposure, thereby achieving a lower failure rate.

Area light source comparison

Combined with optical film technology, COB LED displays can achieve a more uniform and wide light source to avoid glare. It also can achieve a smaller pixel pitch, effectively shortening the optimal viewing distance and providing better display effects. Due to the pixel pitch of SMD LED screens being larger, when viewed at a close distance, pixel blocks will be clearly visible, affecting the picture quality.

Protective comparison

The surface treatment technology used by COB LED display can prevent the LED from failing due to water, moisture, or external force damage, making the LED display more dust-proof and moisture-proof and durable. If the COB LED screen adopts IP65 waterproof, anti-static, and anti-scratch design, it can be cleaned with water or alcohol, and people can use it with more confidence. In contrast, due to the weak surface protection of SMD LED display screens, it is easier to cause lamp beads to fall off or dead lamps.

To sum up, COB LED display is better than traditional SMD LED display in many aspects such as display effect, protection, stability, and performance.

Conclusion:

COB LED screen is an emerging packaging technology LED screen with broad development prospects. Compared with traditional SMD LED screens, COB LED screens have smaller pixel pitch, lower power consumption, and more uniform colors, so they have the potential to be widely used in indoor advertising, stage performances, conference displays and other fields.

With the continuous advancement of LED technology and the increasing demand for high-quality visual experience, and as the manufacturing technology continues to mature, the cost of COB LED screens will gradually decrease, and COB LED screens will surely become one of the mainstream products in the LED display industry.